About Boyum IT Solutions and Codec

Boyum IT Solutions is an award-winning software company with over 25 years of experience delivering ERP add-ons and digital transformation tools for Microsoft Dynamics 365 Business Central. With a presence in 130+ countries and a network of 1,100 partners, Boyum helps SMEs unlock efficiency and visibility across operations.

As a trusted Boyum partner, Codec integrates these solutions into Business Central environments, providing tailored implementations and support to help manufacturers achieve streamlined, connected workflows.

The Manufacturing Challenge

Manufacturers often face:

- Unreliable planning data causing overloaded resources and unrealistic delivery promises.

- Limited shop-floor visibility, with paper-based instructions and delayed updates.

These issues lead to bottlenecks, late orders, and underutilised machines. Boyum’s add-ons—Visual Advanced Production Scheduler (VAPS) and Produce—solve these challenges by creating a continuous digital thread from planning to execution.

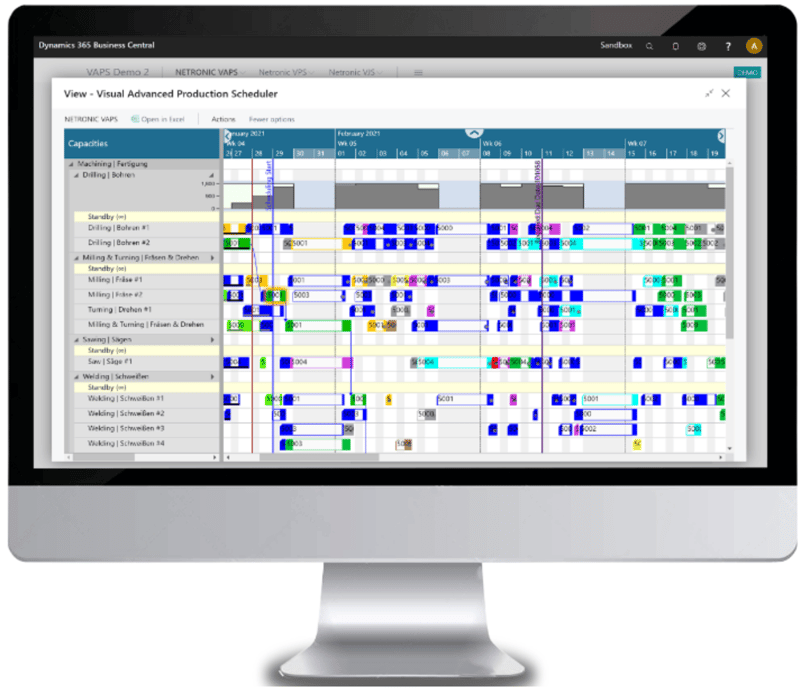

What is VAPS?

VAPS introduces true finite-capacity scheduling inside Business Central, addressing late deliveries and overloaded resources. By visualising constraints and automatically adjusting operations based on available resources, VAPS turns Business Central into a simulation-based planning system.

With VAPS, planners can:

- Build multiple scheduling scenarios and compare outcomes.

- See clear order timelines, resource loads, and conflicts.

- Combine drag-and-drop adjustments with automatic scheduling rules.

- Instantly assess the impact of rush orders without overbooking machines.

- Factor in material availability using EMAD to avoid stalled operations.

- Use alternative machine centers and routing options with conversion factors.

What is Produce?

Produce connects the shop floor to the plan, eliminating paper-based workflows and delayed reporting. It creates a real-time, paperless link between operators and Business Central, ensuring clarity and efficiency.

Built around two applications:

- Backlog Management Tool for production managers.

- Shop Floor Execution Tool for operators.

![]()

Produce enables teams to:

- Organise and prioritise production orders with full visibility.

- Release the right orders to the right work centers at the right time.

- Give operators instant access to materials, instructions, and routing steps.

- Start and stop operations directly from the terminal.

- Record time, material consumption, and finished quantities digitally.

- Monitor progress in real time and know who is working on what.

This reduces errors, accelerates workflows, and ensures Business Central reflects shop-floor activity as it happens.

VAPS + Produce: A Fully Integrated Workflow

Together, VAPS and Produce create a continuous cycle of planning and execution:

- Planners work with reliable, real-time data.

- Operators always have up-to-date instructions.

- Manufacturing becomes streamlined, predictable, and efficient.